28

Introduction

Thermistors are a type of sensitive elements, and they are divided into positive temperature coefficient thermistors (PTC) and negative temperature coefficient thermistors (NTC) according to different temperature coefficients. The typical characteristic of a thermistor is that it is sensitive to temperature and exhibits different resistance values at different temperatures. Positive temperature coefficient thermistors have higher resistance values at higher temperatures, while negative temperature coefficient thermistors have lower resistance values at higher temperatures. They both belong to semiconductor devices.

The development of NTC thermistors has gone through a long period. In 1834, scientists first discovered that silver sulfide has a negative temperature coefficient. And then in 1930, scientists discovered that cuprous oxide-copper oxide also has the performance of negative temperature coefficient, and successfully used it in the temperature compensation circuit of aviation instruments. Subsequently, due to the continuous development of transistor technology, significant progress has been made in thermistor research. In 1960, the N1C thermistor was developed, which is widely used in temperature measurement, temperature control and temperature compensation.

This article introduces some basic information about NTC thermistor, including its working principle, basic parameters, applications and so on.

The NTC Thermistor - A Level Physics

Catalog

Introduction | |

I Definition | |

II Basic Parameters of NTC Thermistor | 2.1 Self-heating |

2.2 Zero-power Resistance | |

2.3 Thermal Time Constant (τa) | |

2.4 Dissipation Coefficient (δ) | |

III Characteristics of NTC Self-heating and Dissipation Coefficient | |

IV Classification of NTC Thermistors | |

V Application of NCT Thermistor | 5.1 NTC Thermistor For Temperature Measurement and Control |

5.2 NTC Thermistor For Temperature Compensation | |

5.3 Wind Speed Measurement | |

5.4 Surge Suppression | |

I Definition

NTC (Negative Temperature Coefficient) refers to the thermistor phenomenon and material with a negative temperature coefficient that decreases exponentially with increasing temperature. This material is a semi-conductor ceramic made of two or more metal oxides such as manganese, copper, silicon, cobalt, iron, nickel, zinc, etc., which are thoroughly mixed, formed, and sintered, and It can be made into NTC thermistor with negative temperature coefficient. Its resistivity and material constant vary with different material composition ratios, sintering atmosphere, sintering temperature, and structural state. At present, there are non-oxide NTC thermistor materials such as silicon carbide, tin selenide, tantalum nitride, etc.

Most of the NTC thermosensitive ceramics are oxide ceramics with spinel structure or other structures, which have a negative temperature coefficient. The resistance value can be approximated as:

In the equation, RT and RT0 are the resistance values at temperature T and T0, respectively, and Bn is the material constant. The ceramic grain itself changes its resistivity due to temperature changes, which is determined by the characteristics of the semiconductor.

II Basic Parameters of NTC Thermistor

2.1 Self-heating

When we measure and use NTC, we always pass a certain amount of current, which causes NTC to generate heat itself. The self-heating of NTC will cause the decrease of its resistance, and dynamic changes will occur during measurement and application. Therefore, controlling self-heating is the key to using NTC. When NTC is used for temperature measurement, self-heating should be avoided as much as possible; when NTC is used for liquid level or wind speed measurement, self-heating is needed.

2.2 Zero-power Resistance

Zero-power resistance is the most basic parameter of a thermal resistor. The resistance values given by the manufacturers are all zero power, but it is easy to get confused about the word "zero power" (because zero power detection does not exist in the physical sense), so its engineering meaning is that the change in resistance caused by self-heating is negligible compared to the total measurement error. Generally, the zero-power measurement of NTC is performed in a constant temperature bath. There are two main factors that affect the total measurement error: one is the current through the NTC, and the other is the accuracy of the constant bath. Generally speaking, there are many ways to reduce the current through the NTC. Once the current drops to a certain degree, it is often the accuracy of the thermostat that affects the total error.

Calculation method: If the temperature T is around 25 ± 0.2, it can be converted into the resistance value at 25 ° C according to the following formula:

R25 = RT / (1 + α25 (T-298)).

In the formula: a is the temperature coefficient of the thermistor under test at 25 ° C.

2.3 Thermal Time Constant (τa)

It refers to the thermal inertia of the thermistor. To be more specific, this means the time required for the temperature of the resistor to change from the initial value to 63.2% of the final temperature difference, even if it is in the reactive power state or the ambient temperature changes suddenly. In general, NTC enters the set (and required medium) temperature environment under stable room temperature conditions quickly, and measures the time required for its temperature to rise by a specified range.

2.4 Dissipation Coefficient (δ)

The power consumed for increasing the temperature of NTC by 1K is called the dissipation coefficient.

The calculation method is as follows:

Δ = U TH · I TH / (T b- T a) W / ℃

In the formula: U TH is the terminal voltage of NTC; I TH is the current flowing through NTC; T b is the self-heating stable temperature; T a is the room temperature.

It can be seen that the rise in NTC temperature refers to the self-heating temperature. From another perspective, the temperature rise caused by self-heating can be calculated by using δ.

For example: Given that δ is 0.1 W / ° C and measuring U TH · I TH is 0.5 W, then:

(T b- T a) = U TH · I TH / δ ℃ = 0.5 /0.1 ℃ = 5 ℃

Self-heating makes NTC 5 ° C above ambient temperature.

NTC Thermistor

III Characteristics of NTC Self-heating and Dissipation Coefficient

When measuring the dissipation factor δ, China's "National Standard" requires that it should be performed in still air. The measurement is usually performed in a glass frame of a specified container. In a room where the air is relatively stable (no flowing air is felt), the temperature inside the glass frame is the same as room temperature. The zero-power resistance value should be measured first, if the resistance value does not change when the glass frame is removed, then we can measure the dissipation factor. After the self-heating reaches thermal equilibrium, which means the current through NTC and its terminal voltage are in a stable state. If the current or terminal voltage fluctuates, and the steady state is lost after the glass frame is dropped, it shows that the weak same-temperature airflow in the room affects the dissipation coefficient, but little impact has been brought on the zero power resistance value. Obviously, the sensitive response to the flowing air after the self-heating of NTC is a useful feature.

NTC Thermistor

IV Classification of NTC Thermistors

In terms of purposes, NTC thermistors can be divided into temperature-sensing NTC and power-type NTC, among which temperature-sensing NTC is used for temperature measurement, temperature compensation and temperature protection, etc. The electrical characteristic is that R25 is relatively large (KΩ level) and the maximum allowable working current is very small (mA level), which requires higher accuracy of R25 and B values. The Power type NTC is mainly used to suppress the inrush current of the line, which is characterized by small R25 (several Ω level), large maximum steady-state current (ampere level), thermal time constant, dissipation factor, and rated current.

Here are several types of NTC thermistors in the following content.

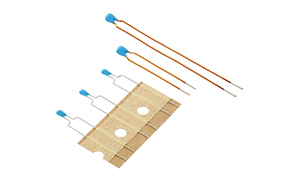

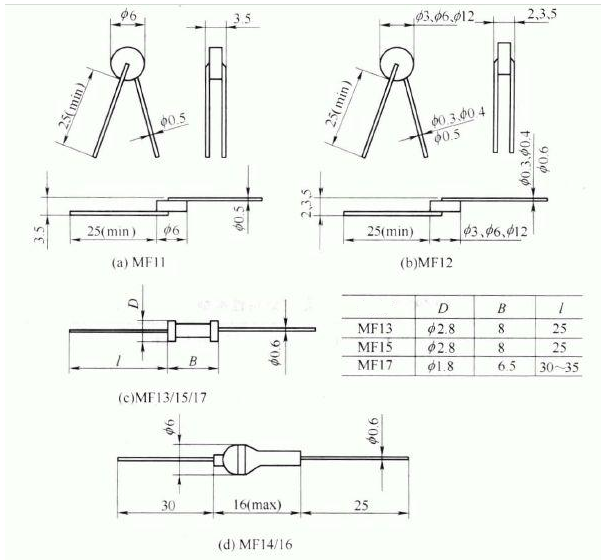

(1)The Common Type NTC Thermistor

It is suitable for temperature compensation of ac and dc electronic equipment, which can also be used for measurement and temperature control.

The Outline and Basic Parameters of NTC Thermistor

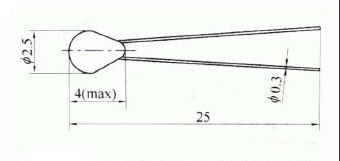

(2)MF52 Beaded NTC Thermistor

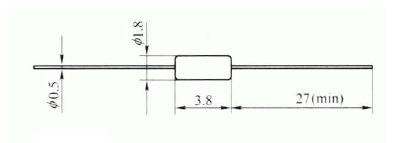

Mf52 bead thermistor has the characteristics of small size, high precision, fast response time and good stability, which is suitable for electronic thermometer, temperature compensation circuit and temperature sensor. Its shape is shown in the figure.

MF52 Beaded NTC Thermistor

(3)MF54 High-precision NTC Thermistor

MF54 high-precision NTC thermistor is made by ceramic and semiconductor processes. As is shown in the figure, it is a glass package structure with axial lead wires at both ends. This product has the characteristics of high resistance precision, small volume, stability, high reliability, fast response speed and high sensitivity, especially suitable for home appliances and automation equipment for temperature control and temperature detection. In addition, it can be used in instrument coil, integrated circuit, quartz crystal oscillator and thermocouple for temperature compensation.

MF54 High-precision NTC Thermistor

(4)Indirectly Heated NTC Thermistor

The NTC thermistor has a heating element inside, and the resistance value of the resistor changes along with the heating current. The resistor and the heating element are enclosed in a high vacuum glass envelope. The NTC thermistor is mainly used as an automatic adjustment element or a non-contact variable resistor in long-distance communication lines and other automatic adjustment systems.

V Application of NCT Thermistor

5.1 NTC Thermistor For Temperature Measurement and Control

There is a relationship between negative resistance and temperature (R / T) in NTC temperature thermistors. The relatively large negative response of an NTC thermistor means that even small changes in temperature can cause significant changes in its resistance. They are therefore ideal for accurate temperature measurement and control. ·

NTC temperature thermistors can be used in electronic thermometers, electronic calendars, electronic clock temperature displays, electronic gifts; heating and heating equipment, heating thermostats; automotive electronic temperature measurement and control circuits; temperature sensors, temperature instruments; medical electronic equipment, electronic toilet equipment, Mobile phone batteries and charging appliances.

How to Test a NTC Sensor Washing Machine, Tumble Dryer, Dishwasher Etc.

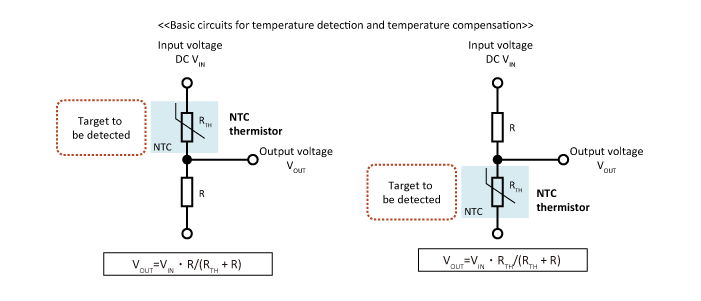

5.2 NTC Thermistor For Temperature Compensation

Many semiconductors and ICs have temperature coefficients and require temperature compensation to achieve a stable performance over a wide temperature range. NTC thermistors are widely used for temperature compensation due to their high temperature coefficients.

Basic Circuits For Temperature Detection and Temperature Compensation

5.3 Wind Speed Measurement

5.3.1The Basic Principle of Measuring Wind Speed By NTC

In addition to temperature measurement, NTC has many comparable advantages in measuring wind speed, which may enable it to have the potential to replace other measurement and control methods.

According to the above description of the measurement of the dissipation coefficient δ, the sensitivity of NTC to air flow performance in the self-heating state indicates that it has the potential to measure wind speed. Under the same temperature and electrical conditions, for example, in a stable room temperature environment, a constant current is generated for the NTC to generate self-heating. During the measurement, the NTC is first placed in still air, and the terminal voltage is minimum at this time, and then the wind speed gradually increases. In the meantime, terminal voltage also show an increasing trend. Due to the decrease of self-heating temperature of NTC caused by flowing air, the resistance value increases, so the larger the air velocity, the more obvious the temperature drop as well as the more significant increase of resistance value. In turn, when we know the degree of NTC self-heating drop (the magnitude of the terminal voltage value), we can measure the wind speed.

The air temperature is different in the actual measurement, because the decrease of air temperature will also lead to the decrease of self-heating temperature, so the air temperature should be measured at the time when measuring the wind speed. Once the air temperature is known and the parameters (the size of the terminal voltage) of the self-heating temperature decrease with the increase of wind speed under this temperature condition are known, the measurement of wind speed can be completed after processing the two data.

5.3.2 Applicable Places

NTC can also be widely used in places where the wind speed and volume have to be measured, which is not only cheap but also extremely simple in circuit structure. E.g:

(1) Dust removal notice for the filter of household air conditioner. The NTC can be installed at the air outlet to detect the wind speed. When the detected wind speed has decreased to a specified range compared with the wind speed of the air volume gear, the user is prompted to clean the filter.

(2) Dust removal tips for vacuum cleaners.

(3) Exhaust air monitoring of gas water heaters. When NTC detects the failure that the exhaust is stopped (or blocked), it will cut off the air source and give an alarm.

(4) Air-conditioning metering, which separately measures the centralized air-conditioning supply system. The NTC metered wind speed installed at the air outlet (then considering the area of the air outlet, average wind speed and other factors) can achieve separate charging for centralized cooling.

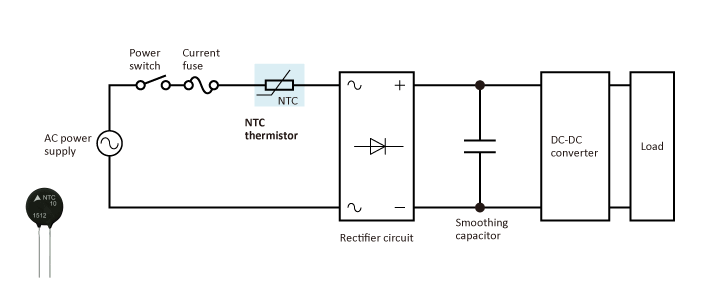

5.4 Surge Suppression

In order to avoid the surge current generated in the electronic circuit at the moment of starting up, connecting a power-type NTC thermistor in series in the power circuit can effectively suppress the surge current. Moreover, after the inrush current suppression is completed, the resistance of the power thermistor will drop to a very small level due to the continuous effect of its current. The power it consumes is negligible and will not affect the normal working current. Therefore, using a power NTC thermistor in the power circuit is the simplest and most effective measure to suppress the surge current in the boot and protect electronic equipment from damage.

NTC Thermistors for Inrush Current Limiting

You May Also Like:

How to Test Different Kinds of Resistors with a Pointer Multimeter

The Functions and Applications of Resistors

Ordering & Quality

| Photo | Mfr. Part # | Company | Description | Package | Qty |

|

XC7K325T-2FFG900C | Company:Xilinx | Remark:IC FPGA 500 I/O 900FCBGA | Package:900-BBGA, FCBGA |

XC7K325T-2FFG900C Datasheet |

In Stock:1043 Inquiry |

Inquiry |

|

MC9RS08KA1CPC | Company:NXP / Freescale | Remark:IC MCU 8BIT 1KB FLASH 8PDIP | Package:8-DIP (0.300", 7.62mm) |

MC9RS08KA1CPC Datasheet |

In Stock:91 Inquiry |

Inquiry |

|

MC33910G5AC | Company:NXP | Remark:IC SYSTEM BASIS CHIP 32LQFP | Package:32-LQFP |

MC33910G5AC Datasheet |

In Stock:5153 Inquiry |

Inquiry |

|

BAS70KFILM | Company:STMicroelectronics | Remark:DIODE SCHOTTKY 70V 70MA SOD523 | Package:SC-79, SOD-523 |

BAS70KFILM Datasheet |

In Stock:79020 Inquiry |

Inquiry |

|

MC9S08JR12FAE | Company:NXP / Freescale | Remark:IC MCU 8BIT FLASH 48LQFP | Package:48-LQFP |

MC9S08JR12FAE Datasheet |

In Stock:83598 Inquiry |

Inquiry |

|

CAP017DG | Company:Power Integrations | Remark:IC CAP DISCHRG 1000V 2500NF 8SO | Package:8-SOIC (0.154", 3.90mm Width) |

CAP017DG Datasheet |

In Stock:7450 Inquiry |

Inquiry |

|

MC33742PEG | Company:NXP / Freescale | Remark:IC SYSTEM BASE W/CAN 28SOIC | Package:28-SOIC (0.295", 7.50mm Width) |

MC33742PEG Datasheet |

In Stock:28162 Inquiry |

Inquiry |

|

RC0603FR-071KL | Company:Yageo | Remark:RES SMD 1K OHM 1% 1/10W 0603 | Package:SMD |

RC0603FR-071KL Datasheet |

In Stock:39061200 Inquiry |

Inquiry |

|

MAX14515EWA+T | Company:Maxim Integrated | Remark:IC LENS DVR SMALL LIQUID 8-WLP | Package:8-WFBGA, WLCSP |

MAX14515EWA+T Datasheet |

In Stock:9184 Inquiry |

Inquiry |

|

MC68360ZQ25L | Company:Freescale Semiconductor - NXP | Remark:IC MPU M683XX 25MHZ 357BGA | Package:BGA |

MC68360ZQ25L Datasheet |

In Stock:811 Inquiry |

Inquiry |